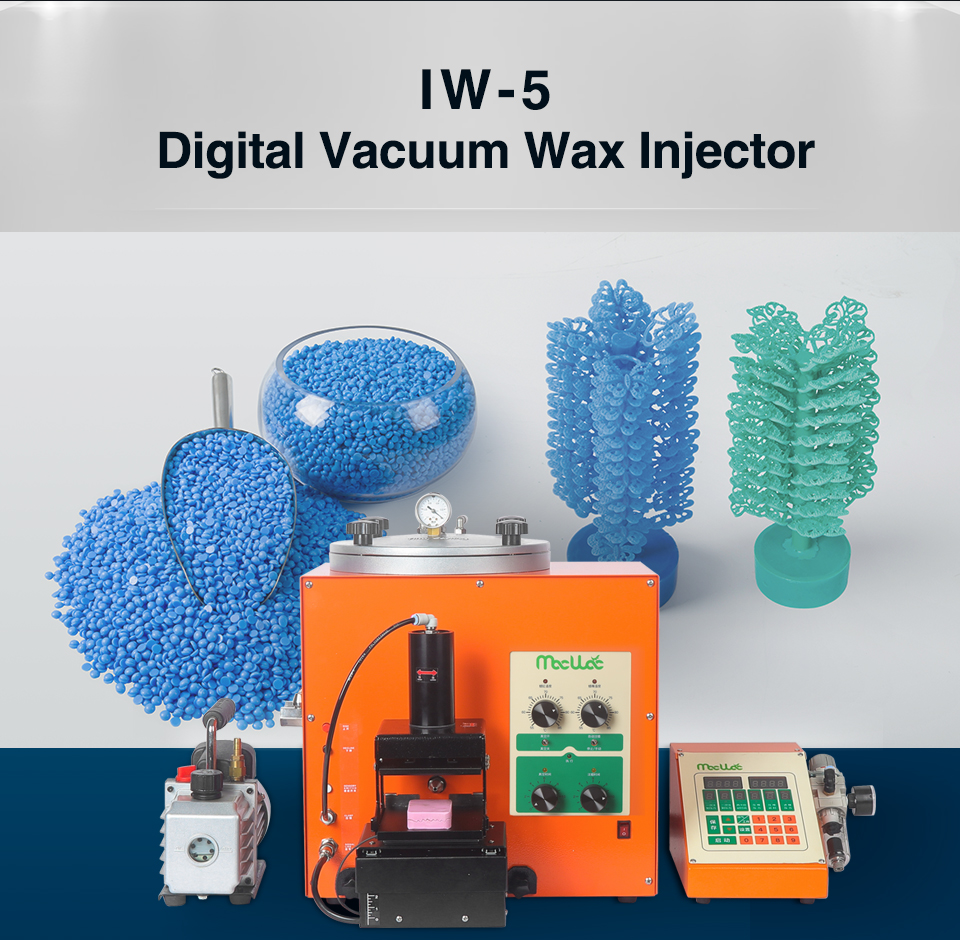

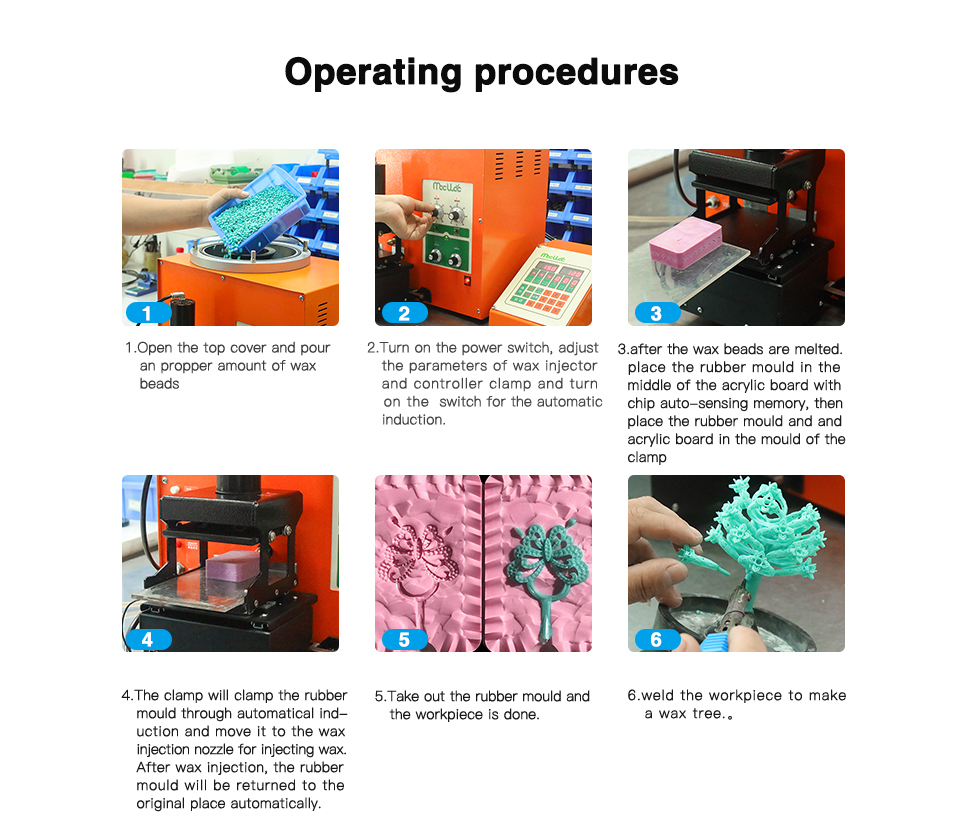

Enhance your small factory's production efficiency with the IW-5 Vacuum Wax Injector. This industrial-grade machine boasts stable air pressure and precise temperature control, ensuring reliable operation for wax injection processes. Featuring 10 programmable groups, it accommodates diverse design and production requirements. The IW-6 offers versatility with two modes: manual button control and electromagnetic induction, allowing flexibility in operation. For added safety, it includes an emergency stop switch to halt operations promptly when necessary. The machine's automatic lifting clamp further streamlines workflow, enhancing productivity in your workshop. Built with components sourced from top-tier brands, the IW-6 Vacuum Wax Injector guarantees durability and performance, making it an essential tool for jewelry and small-scale manufacturing industries.

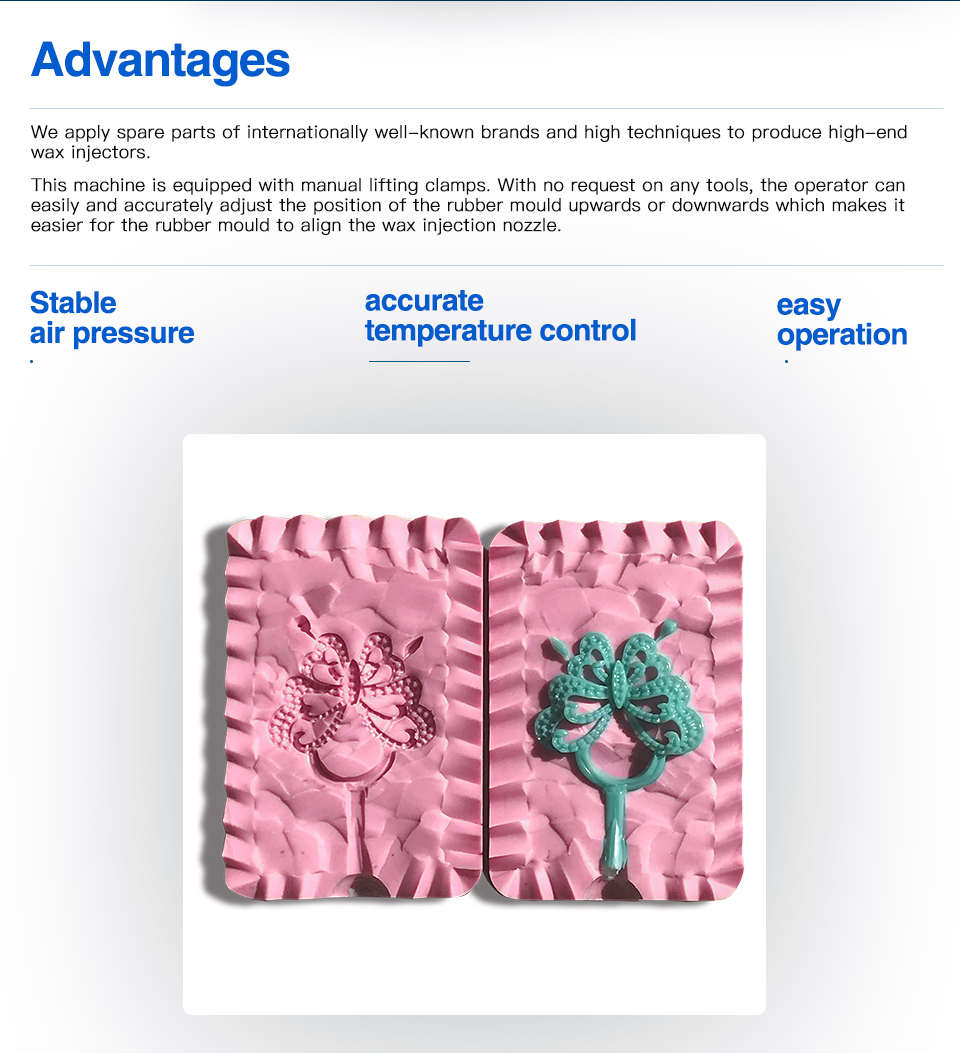

Advantages:

Programmable: Equipped with 10 program groups, catering to the diverse design and production requirements of small factories.

Dual Operating Modes: Offers both manual button control and electromagnetic induction modes for enhanced versatility and efficiency.

Safety Feature: Incorporates an emergency stop switch, allowing for immediate halt of the machine in case of emergency.

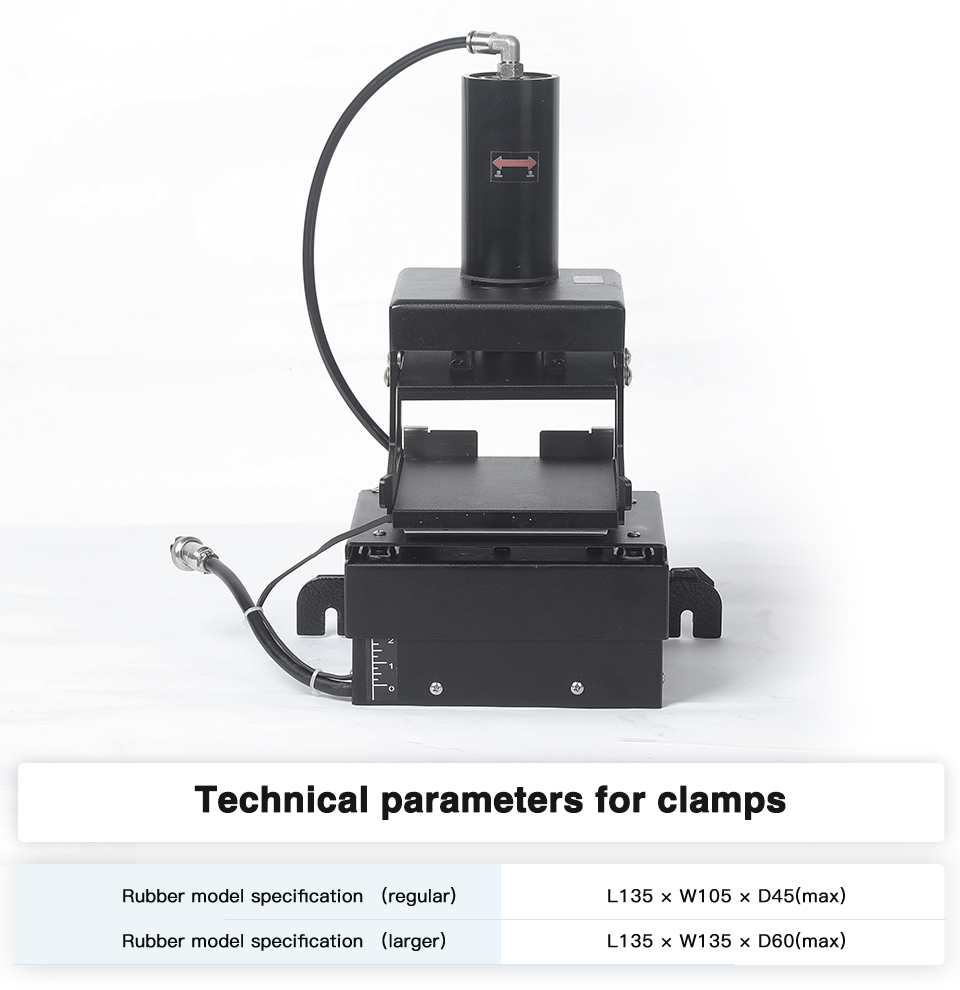

Automated Lifting Clamp: Features an automatic lifting clamp for streamlined and hassle-free operation.

Stable & Reliable: Ensured by industrial-grade construction, stable air pressure, and precise temperature control, ensuring consistent performance.

High-Quality Components: Components sourced from first-line brands, guaranteeing longevity and optimal performance.

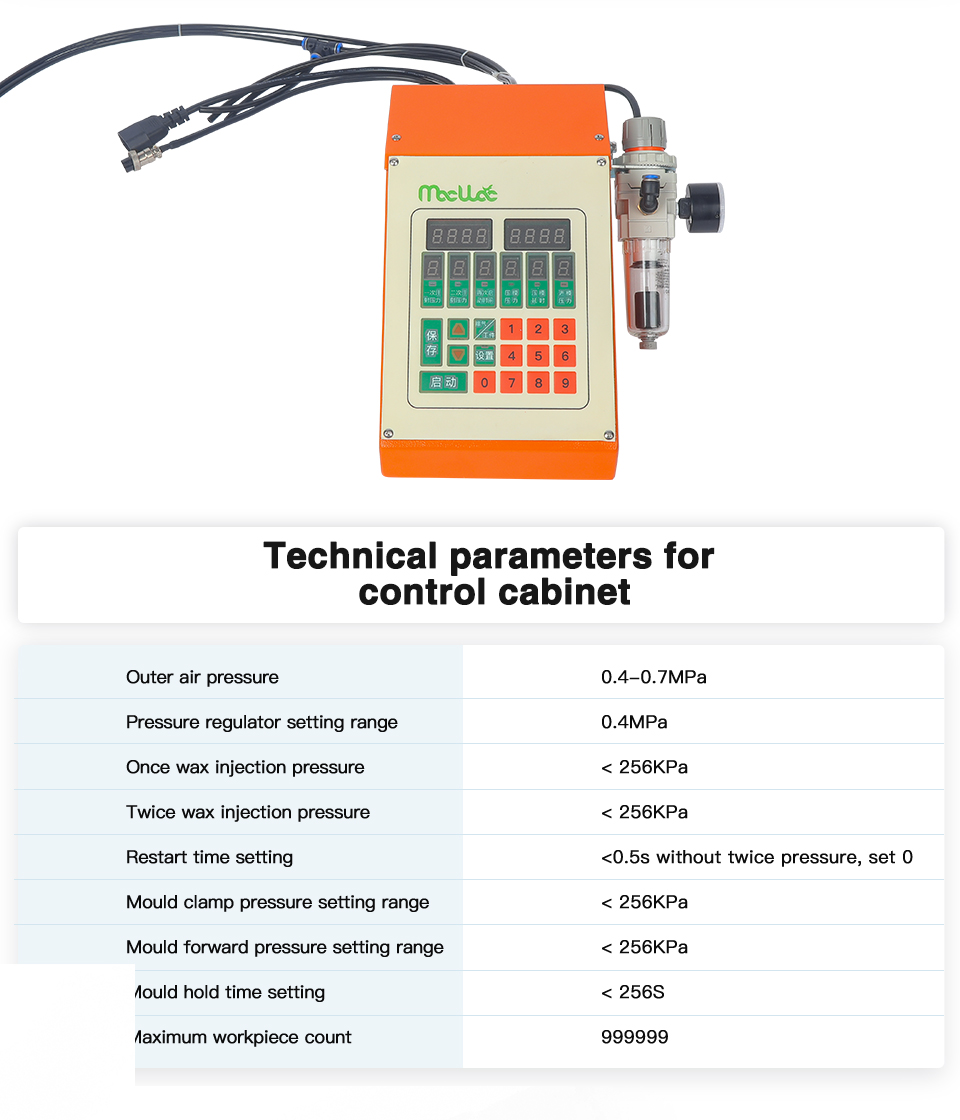

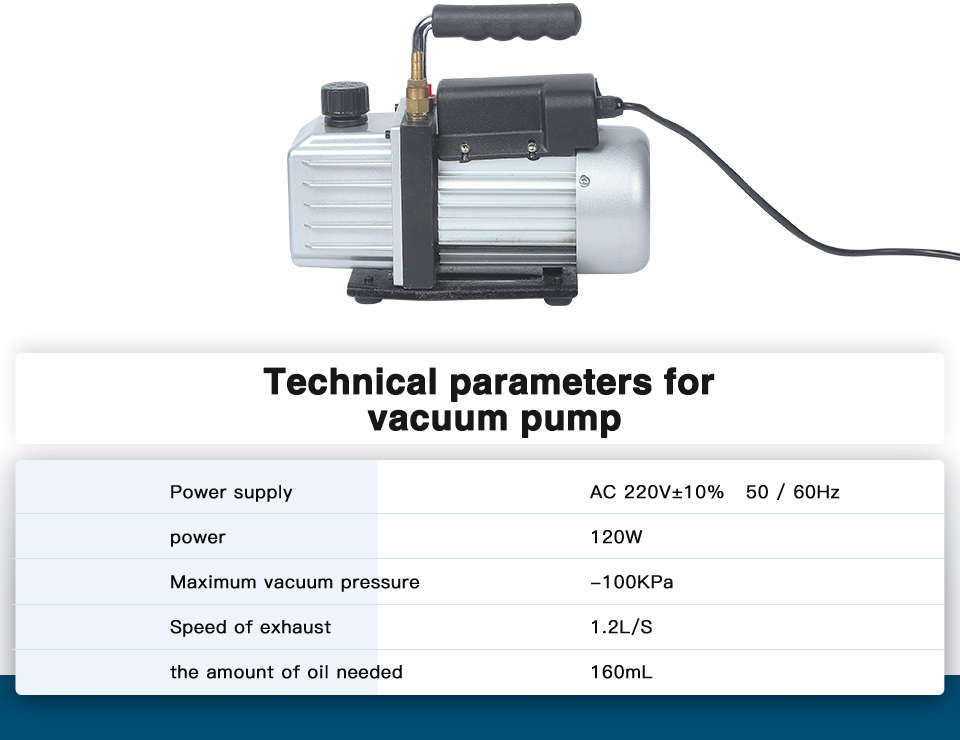

Technical parameters

| Voltage | AC220±10%V, 50/60HZ, 1Phase |

| Power Input | 500W |

| External input pressure | 0.4~0.7MPa |

| Pressure regulator setting range | 0.25~0.3MPa |

| Pressure sensor display range | -5~240KPa |

| Mold Clamp pressure setting range | 30~235Kpa |

| Mold forward pressure setting range | 65~235Kpa |

| Wax tank setting pressure | Less 200Kpa |

| Fuse specification | 5A/250V |

| Mold hold mould setting range | 0~300(s) |

| Wax tank capacity | 3kg |

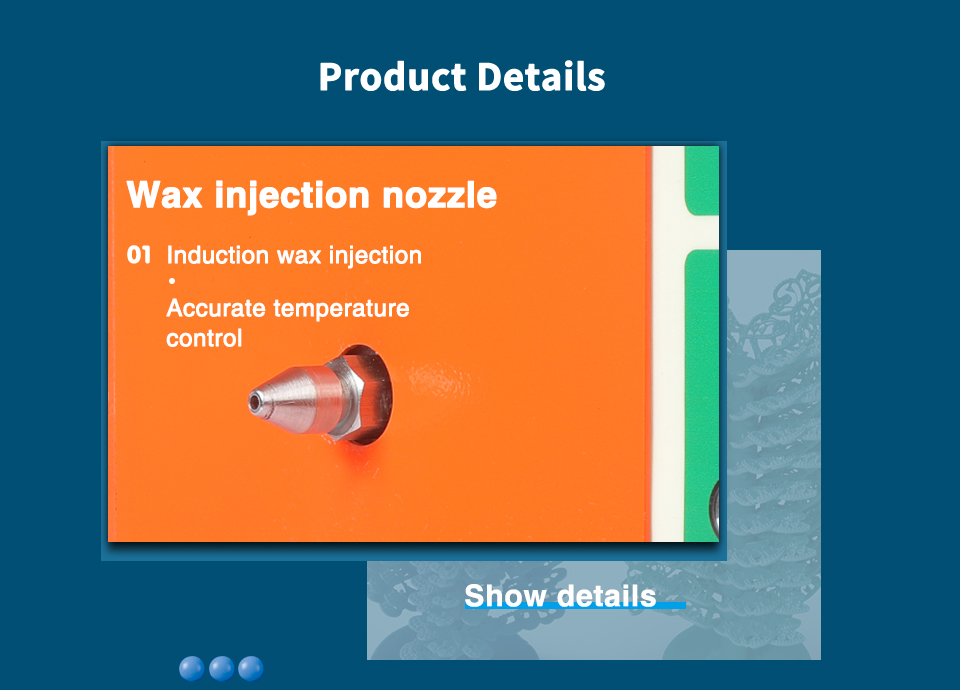

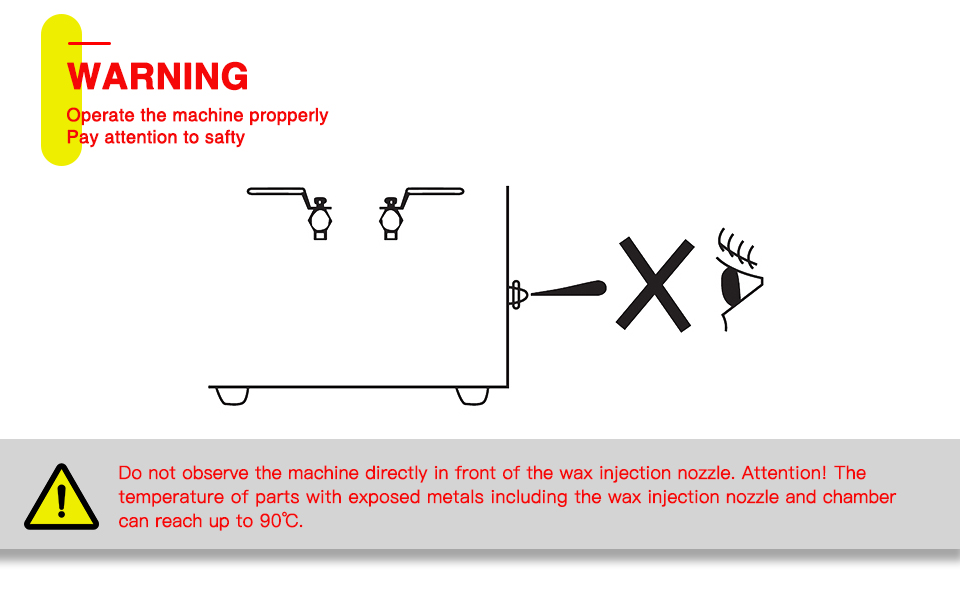

| Heating temperature range of wax bath | 0-95℃ |

| Wax nozzle heating temperature range | 0-95℃ |

| Vacuum time setting range | 0~25(s) |

| Injection time setting range | 0~25(s) |

| Maximum workpiece count | 0~9 |

| Start | magnetic induction or button |

| Total amount of data stored | 10 group |

online service

online serviceScan to wechat :